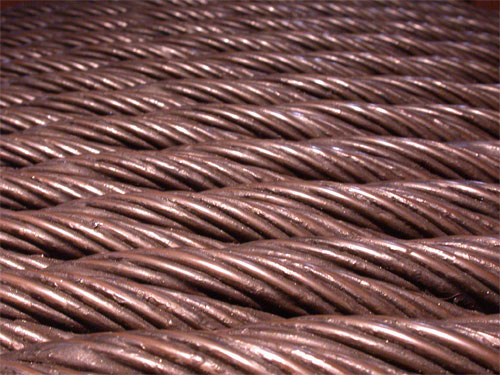

THE CABLE Andrew Hallidie is considered the father of the cable car, although he was not the only inventor to dabble in the use of cable as a means of transportation. Hallidie and his father both held several patents for the manufacture and use of cable, or wire rope as it was called. Wire rope served a number of purposes in the mines of California, Nevada and other western mining centers in the latter half of the 19th century. Woven much like hemp rope but much stronger, it ranged in gauges from the thickness of a hair to a finger, and was used to transport ore from the mines, equipment and supplies to the mines, and occasionally passengers as well, who both trembled and wondered at the breathtaking views they saw from the aerial trams operating on the wire ropes. The first commercial success of wire rope was in England when, in 1830, George Binks convinced the Royal Navy to replace hemp rope on its fleet of ships with wire rope. Binks was joined shortly after by Andrew Smith, a Scot, who held patents on several improved varieties of wire rope and was incidentally the father of young Andrew, who took the name Hallidie from his godfather Sir Andrew Hallidie, royal physician to the court of Queen Victoria. Across the water in the United States, John A. Roebling, who would later build the Brooklyn Bridge, was manufacturing wire rope at his factory in Pennsylvania, in 1840. Roebling's company expanded, as did the demand for wire rope, until it became one of the largest producers of iron and steel rope used in building bridges during the 19th century. One of Roebling's friends and competitors, Peter Cooper, began dabbling in aerial tramways to transport materials for factories on the East Coast. Hallide developed the first successful aerial tramways in the West, after a few years of drifting from camp to camp working claims, narrowly avoiding disasters both natural and manmade, and briefly running a restaurant at Michigan Bluff in the Mother Lode. Then in 1855, young Hallidie built a wire suspension bridge and aqueduct 220 feet long at Horse Shoe Bar on the Middle Fork of the American River. A year later he built a flume near Gray Eagle Bar that transported ore to a quartz mill 1100 feet up a hill. The cars operated along Hallidie's wire rope, which replaced regular rope, by gravity, the loaded cars pulling empty ones up to the mill as they went down. Hallidie manufactured rope for this project consisting of three spliced pieces one-eighth of an inch thick, 1200 feet long, which lasted for two years as opposed to 75 days for the previous type used. In 1857 Hallidie left the Mother Lode and returned to San Francisco where he set up a factory on the corner of Mason and Chestnut Streets to manufacture wire rope. In addition to aerial tramways, his rope was used to build suspension bridges across creeks and rivers throughout northern California. He was often away from the City on his bridge projects until in 1865 he returned to San Francisco and focused his energies entirely on manufacturing and perfecting wire rope. The discovery of the Comstock Lode in Nevada increased the need for wire rope. The City became a major industrial center for mining operations in the 1860s and Hallidie prospered, becoming a leading entrepreneur, citizen, and in 1868 President of the prestigious Mechanic's Institute. It was also about this time that Hallidie began to implement a scheme for urban transportation he had been pondering for some time, based upon his use of wire rope for aerial tramways transporting material up steep mountainsides and across gorges. He worked on improving the tensile strength and flexibility of his wire to develop an "endless" wire rope that could be would around large pulleys, which could then provide continuous underground propulsion for a car that could be attached or released at will from the cable. Hallide took out a patent for this "Endless Wire Ropeway" and for the next decade or so dominated the construction of tramways at mines across the west. However, it was the implementation of his Endless Wire Ropeway for moving streetcars in San Francisco that brought him lasting fame and a place in the history books.    If a cable should break, which is very rare, the splice is made temporarily out along the line, then run back into the powerhouse where a permanent splice is made. The cable is lubricated to reduce wear and friction; for over a century pine tar was used, giving the cable car lines a distinctive and now nostalgic smell, but after the 1982 restoration a synthetic lubricant was substituted. |

The Cable |

|

Cable Car Museum - 1201 Mason Street - San Francisco © 2004 - 2021 Friends of the Cable Car Museum